If you are an online seller who supplies products to different locations, you will know the hassle of monitoring your inventory. Every day you wake up to fresh batches of orders from Jabalpore, Vishakapatnam, Indore, Panaji, and Mizoram. If your head spins at the sight of different cities, then multi-warehouse management is the answer for you.

There are many benefits to spreading your footprint including:

- The benefits of scale – it works out cheaper by reducing transport costs.

- Prompt service – products reach customers quicker than if you have to transport from a single location.

- It permits expansion – you can serve more locations thereby expanding your business.

- Helps minimise risk – as long as you don’t put all your eggs in a single basket, you are mitigating your risk.

However, managing different warehouses has associated chaos too. Here are some handy tips to help you retain your sanity while juggling inventory.

Tip #1 – Sign up for software that helps you keep track of things

Having a software helps you monitor the stock in different warehouses in different locations. This helps you hold up the fort if one of the warehouses doesn’t have a product. If (by some oversight) the warehouse that supplies to Vishakapatnam has exhausted a product, you can direct it from the Panaji warehouse.

Tip #2 – Maintain separate records for particular warehouses

Keep the inflow outflow, invoices and other papers separately for each warehouse. Likewise, maintain a separate record

Tip #3 – Have systematic stock-taking

Check your stocks regularly to ensure that you don’t run low on any item. Depending on the products you deal in, conduct weekly, fortnightly or monthly checks to gauge the level at each warehouse.

Tip #4 – Segregate your stock keeping unit (SKU) codes

Avoid putting your different SKUs together as it causes confusion. Maintain them separately to simplify the process of monitoring your stock.

Tip #5 – Keep an eye for non-performing units

If you spot any item that is slow moving, or is stuck on the shelves for more than six months, make other plans for it. You don’t want to be spending money to store and maintain something that shows no sign of bringing any profits. Take necessary steps to clear them and replace them with fast moving items.

Tip #6 – Plan the layout well

Ensure that you label all the shelves and have a map with the layout and labels to locate the products easily. Give out a copy of the map to all new recruits. Also, ensure that the map is put up at strategic locations across the warehouse. Likewise, put the fast moving items closer to the exits.

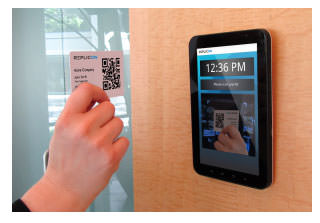

Tip #7 – Ensure employee identification

Install an ID or swipe in system for your employees. This will make sure that unauthorised personnel do not have access to the floor. The presence of non-employees impedes the movement of products. This brings down productivity due to loss of time.

Tip #8 – Comply with safety rules

Mandate safety gear like helmets and gloves for all staff. Do not compromise with training or security in the warehouses. It is a good practise to hold training sessions periodically to sensitise the staff on floor safety. Install fire extinguishers and alarms at strategic locations to handle any untoward incident.

These tips should give you a head start to monitor your different warehouses. If you need more information on multi-warehouse management software, get in touch with Browntape. We are India’s largest ecommerce service provider, and you can choose from our different software and services to help you manage your ecommerce business.